Robotics: Advancing Modern Manufacturing

Post Categories

Angela

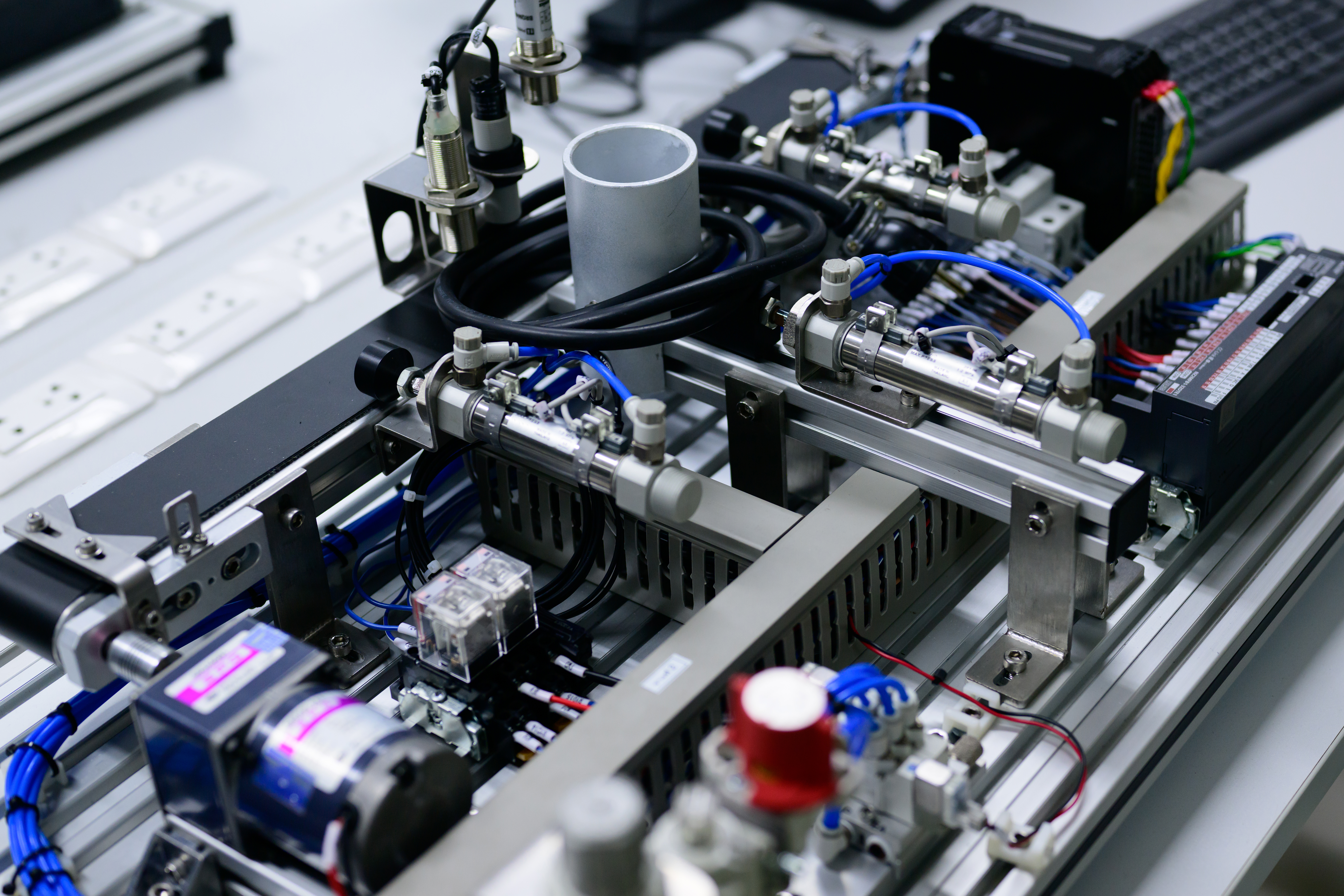

Manufacturing has witnessed a revolution in automation with robotics taking center stage. Robots are central to the manufacturing process, streamlining operations, enhancing efficiency, and reducing labor costs. Let's take a closer look.

The Evolution of Robotics in Manufacturing

1. Early Industrial Robots Robots have a long history in manufacturing, dating back to the 1950s when they were first introduced in factories. Early industrial robots were large and expensive, primarily used for tasks like welding and material handling. While limited in capabilities, they paved the way for further advancements.

2. The Rise of Automation With the development of automation, robots began to play a more substantial role in manufacturing. Tasks that were previously performed by human workers, such as assembly, painting, and quality control, are now completed with robots with greater precision and consistency.

Check out our Trends in Automotive for 2025.

Key Advantages of Robotics in Manufacturing

- Enhanced Productivity One of the most significant advantages of robotics in manufacturing is increased productivity. Robots can work 24/7 without fatigue, resulting in higher output and shorter production cycles. They also excel at repetitive and labor-intensive tasks, allowing human workers to focus on more complex and creative aspects of production.

- Improved Quality and Consistency Robots are incredibly precise, ensuring consistent quality in manufacturing. They reduce the risk of errors, which can lead to product defects or recalls, thus enhancing product quality and customer satisfaction.

- Workplace Safety Dangerous and physically strenuous tasks can be assigned to robots, reducing the risk of workplace injuries and improving overall safety for human workers. Robots can work in environments where exposure to hazardous materials or extreme conditions would be harmful to humans.

- Cost Reduction While the initial investment in robotics can be significant, the long-term cost savings are substantial. Robots can perform tasks around the clock, without breaks, and do not require salaries, benefits, or overtime pay.

Applications of Robotics in Modern Manufacturing

1. Welding and Material Handling Robots have long been used for welding tasks, such as automotive body construction. They are also adept at handling heavy and bulky materials, making them valuable in industries like logistics and construction.

2. Assembly Robotics play a crucial role in product assembly, ensuring precision and speed. In industries like electronics and appliances, robots can assemble intricate components with utmost accuracy.

3. Inspection and Quality Control Robots equipped with advanced vision systems can perform meticulous inspections, identifying even the tiniest defects. This is vital in industries like food processing and electronics manufacturing.

4. Industry 4.0 Integration In the era of Industry 4.0, robots are becoming increasingly interconnected and autonomous. They can communicate with other machines and systems, allowing for real-time data analysis and adaptive manufacturing processes.