Brace for the Impact! 2024 Supply Chain Disruptions

Post Categories

Ralph Hiddenburg, CSCP

2024 Supply Chain Disruptions

The Norm that's Anything But Normal

This is getting serious

In 2024, supply chain disruptions continue to pose significant challenges for US manufacturers. While these disruptions have become somewhat normalized in the industry, they still remain a critical concern, requiring vigilant attention and proactive strategies.

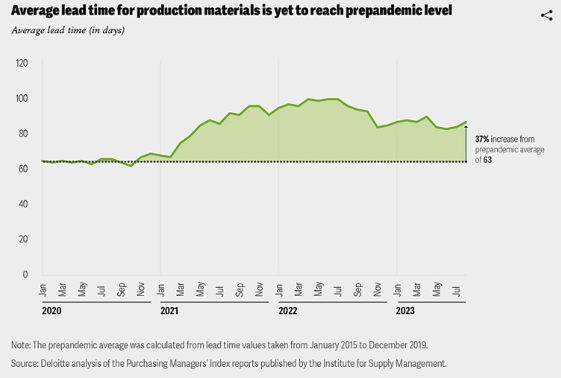

Ongoing VolatilityAs per Deloitte's findings, in August 2023, the average delivery time for production materials reduced to 87 days—a sign of improvement. However, despite this progress, it's evident that we're still a considerable distance away from the efficient delivery timelines seen before the pandemic. Supply chains continue to grapple with unpredictability and volatility, juggling challenges in sourcing raw materials, maintaining inventory, and meeting timely deliveries. These ongoing issues persist due to fluctuations in demand and unexpected external factors, creating an environment fraught with uncertainty. |

|

|

Strikes Impact on Operations In 2023, there were almost 400 strikes, including the notable 46-day strikes led by UAW. The frequency of work stoppages involving 1,000 or more workers surged, hitting the highest count since 2013, according to the Bureau of Labor Statistics. This trend implies the possibility of such events continuing into 2024. These work stoppages and strikes are part of a broader landscape of supply chain disruptions, including shortages of key components, delayed shipments, and logistical bottlenecks. They significantly impact day-to-day operations within manufacturing, affecting production schedules, fulfillment timelines, and ultimately, customer satisfaction. |

|

Cost EscalationMitigating disruptions has typically led to increased expenses for manufacturers. While expediting shipping, seeking alternative suppliers, or stockpiling excess inventory were once common strategies, they've proven inadequate in meeting the challenges of 2024. These actions strain financial resources without adequately resolving the evolving complexities of the current environment. The industrial metaverse, including diverse technologies like AI, are poised to strengthen supply chain resilience in manufacturing. It enables real-time visibility, virtual prototyping for scenario testing, remote monitoring, immersive training, seamless collaboration, and predictive analytics. |

|

Solution

Controlling The Uncontrollable

How effectively manufacturers handle these disruptions can impact their competitiveness. Those adept at managing and mitigating disruptions will have a crucial edge over their competition.

Now more than ever in 2024, it's time to radically upgrade your expectations of what your staffing partner could deliver:

- Flexibility in Talent Supply

By understanding the changing demands of a tech-integrated landscape, they can provide flexible personnel solutions, offering specialists capable of working within the AI-driven processes. - Training and Upskilling

A proficient partner would be able to offer training programs to existing staff, equipping them with the talent needed to operate within this industrial metaverse, further ensuring seamless transition and utilization. - Scalable Solutions

A strategic staffing service can provide upgrades on demand that align with this evolving technology. - Strategic Planning

They would also significantly contribute insights into workforce planning and adapting, in order to accommodate this dynamic industrial metaverse.

Are you ready to navigate through supply chain disruption? Let's schedule a time to talk!